Molybdenum in carbon steel

Molybdenum, often nicknamed as “Moly”, has many important metallurgical effects in HSLA and alloy steels:

- Moly is a potent hardenability agent and, thus, a standard constituent in heat-treatable steels.

- It also retards softening at elevated temperatures and is therefore used in boiler and pressure vessel steels.

- In low-carbon HSLA steel Moly promotes the formation of acicular ferritic structures, which became the backbone of modern high strength pipe steel design.

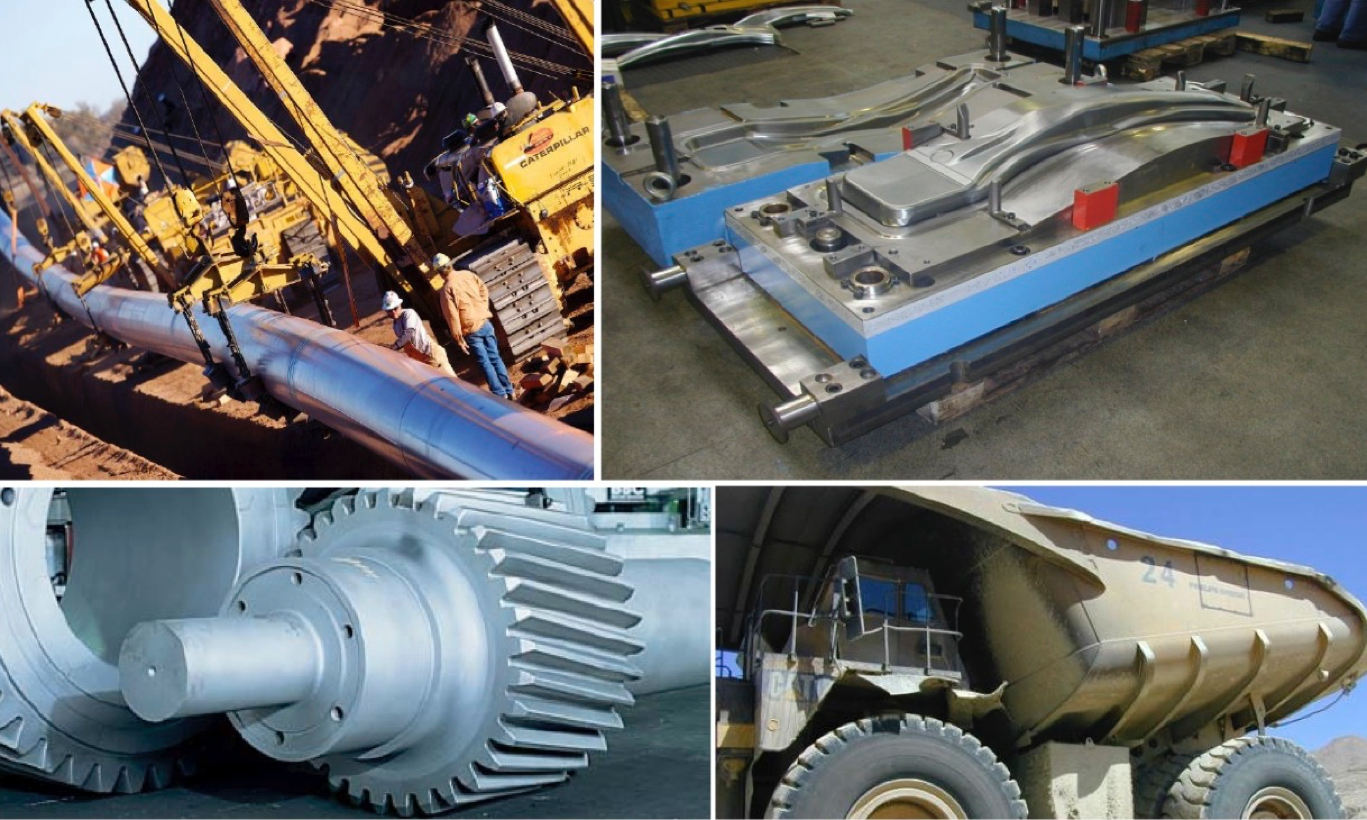

- Other uses are in high strength Q&T steel applied for crane booms, offshore constructions, excavation and mining equipment as well as oil country tubular goods.

- In modern ultrahigh strength automotive steel, Moly alloying is greatly facilitating the processing of the required multi-phase microstructure.

Moly has powerful synergies with Nb, its neighbor in the periodic table of elements. Moly can precipitate during secondary heat treatment increasing the strength. Being in solid solution it controls size and distribution of other primary precipitates such as Nb carbide. This offers considerable benefits with regard to strength, temperature resistance or hydrogen induced cracking resistance.

NiobelCon actively develops Mo-based metallurgy, analyses markets and supports producers as well as users with know-how and expertise.