Niobium carbide

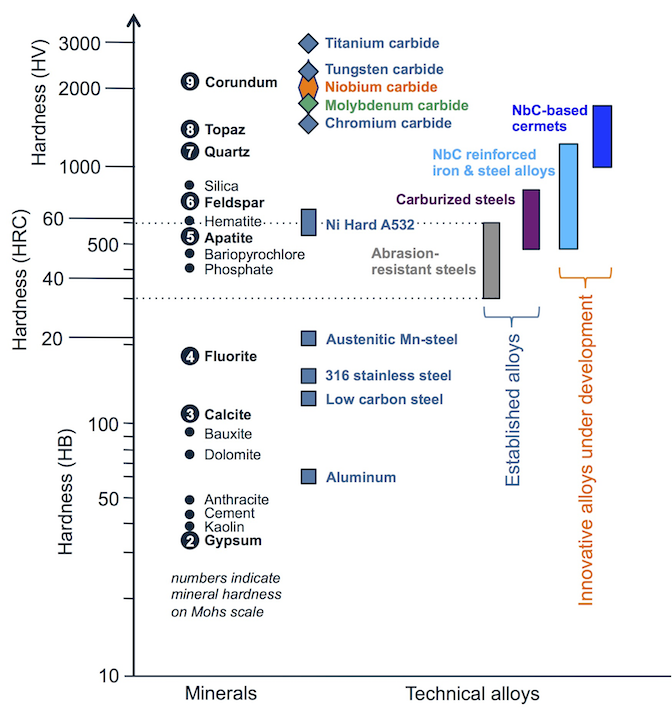

Niobium carbide is amongst the hardest technical compounds known.

It should thus be excellently suited for machining applications and wear protection.

Striking advantages of niobium carbide in industrial applications

- More volume per kg purchased compared to WC thanks to much lower density of NbC.

- Weight reduction achieved with NbC reduces inertia in machining equipment and dynamic applications.

- Reduction of adhesive wear (tooling applications).

- NbC grades show overall reduced friction in tribo-contacts as compared to WC grades.

- Mechanical properties of NbC are comparable to those of WC (wear parts application).

- The hot hardness of NbC is above 700°C similar or higher than that of WC, even hough its hardness at room temperature is lower.

- Rather high chemical stability (low solubility of Nb in iron) reducing the need for additional coating in hot applications.

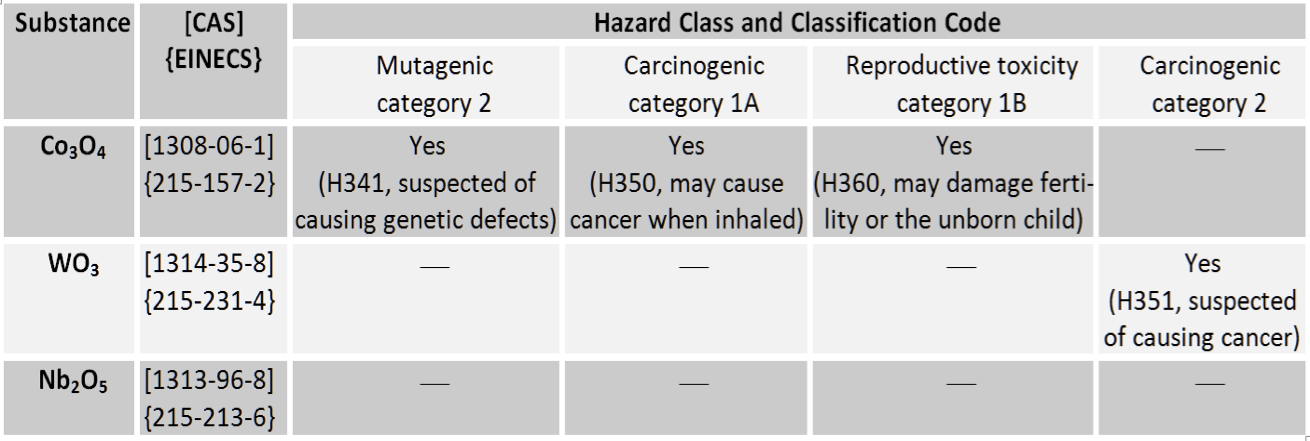

- Tribo-oxidation products of NbC have low environmental impact and health risk since niobium oxide is classified as non-toxic.

Summary of health & safety classifications and labeling within REACH (extract)