Niobium's benefits in automotive flat steel

Modern automotive sheet steel covers a wide range of properties from very soft grades with highest formability to extremely strong grades being very difficult to form. In the same respect the carbon content ranges from nearly zero in interstitial-free steel up to 0.35% in the strongest press hardening steel.

In the widely used HSLA steel grades the addition of carbon is mediated against microstructural optimization with the aim of obtaining high strength steel having acceptable formability and weldability.

Niobium microalloying has been established in these steels as the most efficient element for obtaining grain refinement and precipitation strengthening.

Furthermore, niobium acts as a carbon stabilizer providing steel with an interstitial-free matrix.

These well-known direct metallurgical benefits of niobium are complemented by several less-known indirect effects bringing substantial benefits for either processing the steel in the mill or improving particular properties of the steel. Examples of such indirect benefits are:

- Crystallographic texture control,

- Phase transformation kinetics,

- Stabilization of mechanical properties,

- Improved bendability and flangeability,

- Hydrogen trapping.

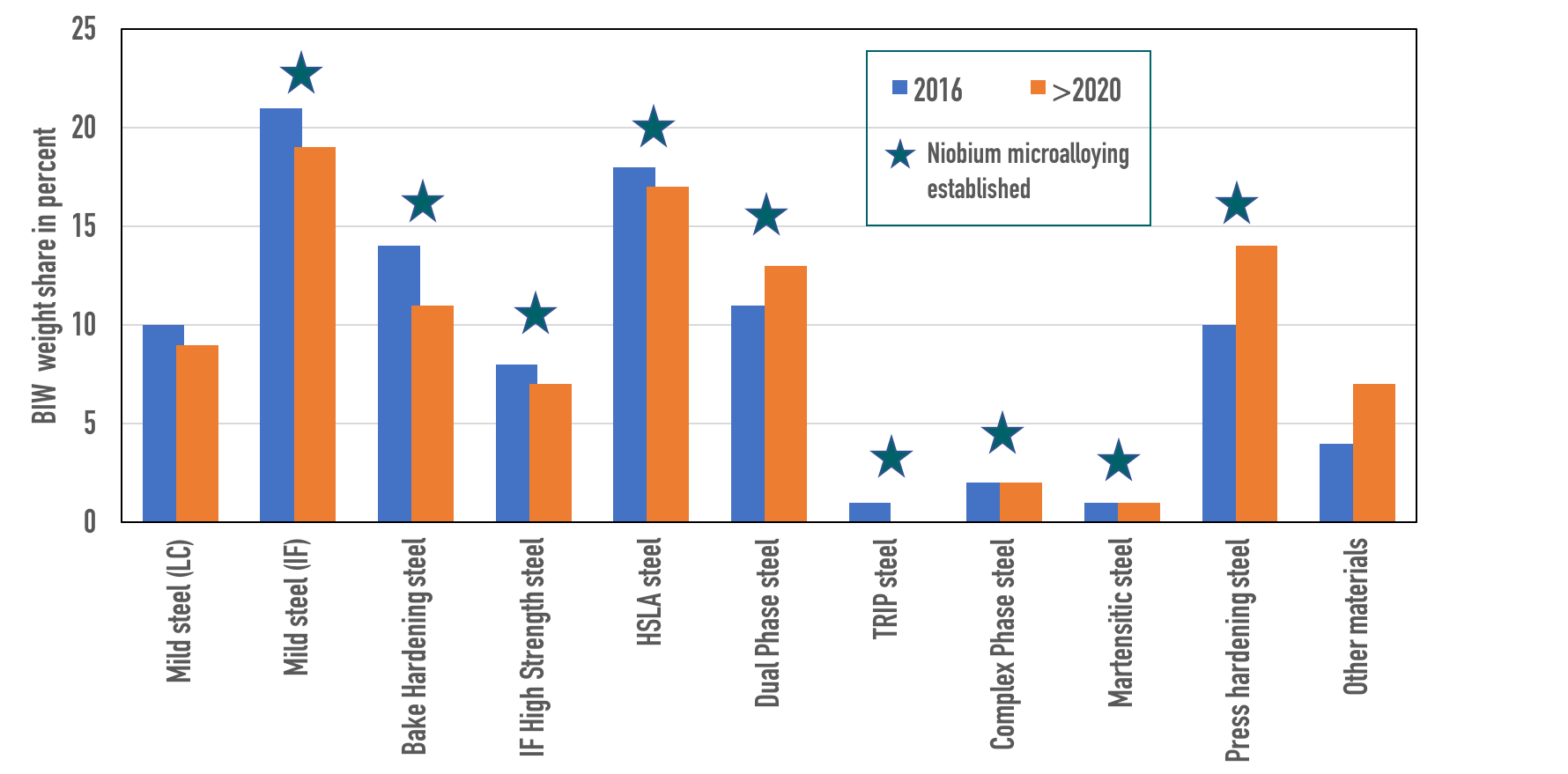

Evolution of BIW material mix in European cars