Niobium in cast iron alloys

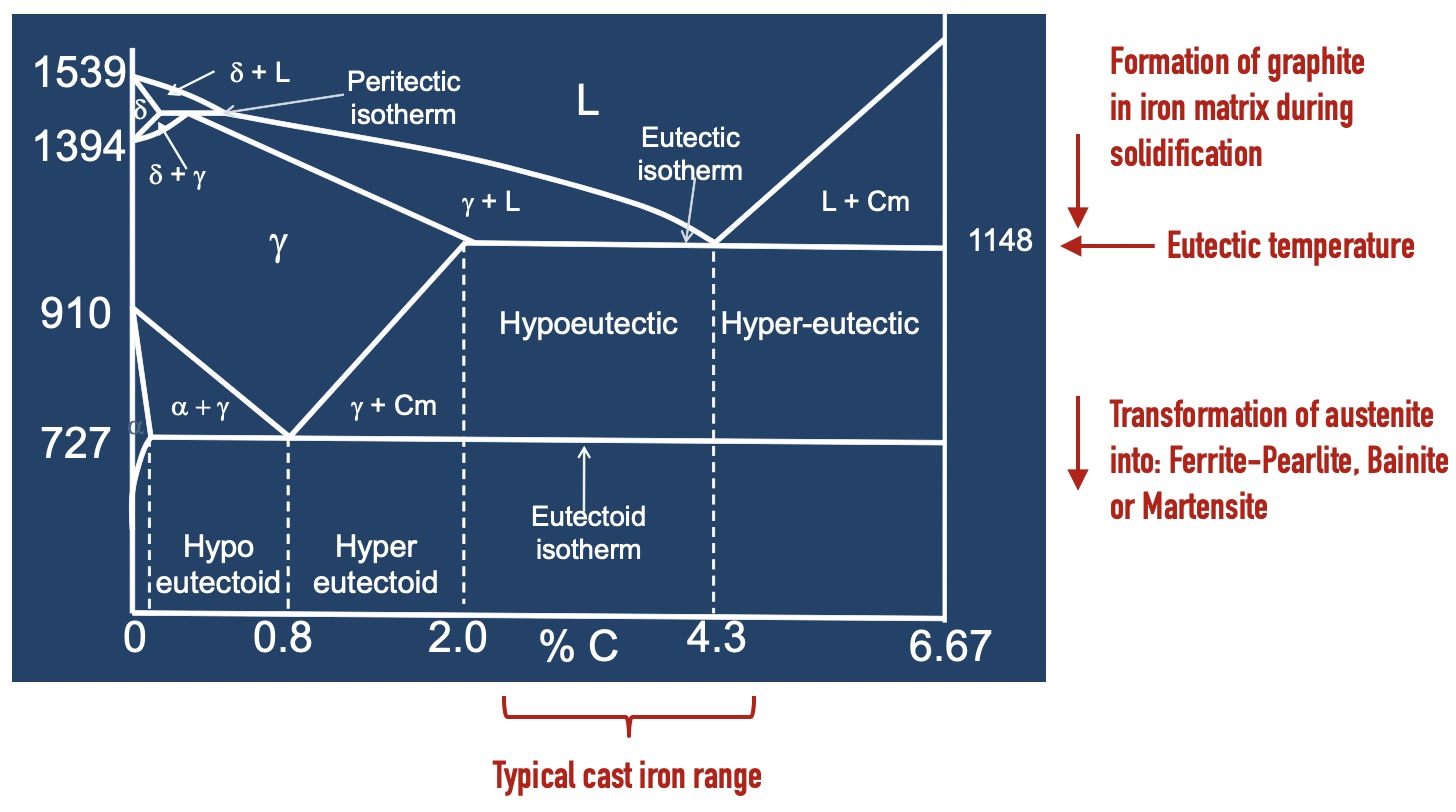

Cast iron alloys generally contain more than 2wt.% of carbon and a variety of other alloying elements of which niobium is clearly one of the less commonly used. Nevertheless, over the years niobium has found its way into specific applications of grey cast iron, white cast iron, ductile iron as well as cast heat-resistant alloys.

Metallurgical functions of niobium in cast iron

Niobium is added to liquid iron typically as ferro-niobium in amounts of up to 2wt.%.

Depending on the amount added it can deploy a variety of effects:

1. Primary NbC precipitation in fully liquid phase

☞ Dispersion of macroscopic hard particles increasing wear resistance

2. Precipitation of NbC in the solidification interval

☞ Can act as nucleation site for graphite (inoculation effect)

☞ Restriction of eutectic cell size

☞ Dispersion of microscopic hard particles increasing wear resistance

3. Nb in austenite

☞ Solute drag on grain boundary

☞ Grain boundary pinning as precipitate

☞ Lowering carbon diffusivity

☞ Delay of phase transformation

4. Nb in ferrite

☞ Strengthening effect by precipitation of ultra-fine coherent particles

While the effects listed under 1 and 2 are specific to cast alloys, the effects listed under 3 and 4 are identical to the ones known in steel alloys. The combination of one or several of these effects allows significantly enhancing the properties and performance of cast iron alloys.